New Holland Haytools & Spreaders

New Holland Discbine® PLUS Center-Pivot Disc Mower-Conditioners - Discbine® 312 PLUS

|

TRANSPORT WIDTH FT. IN. (M) 11’ 10” (3.6) CUTTING WIDTH FT. IN. (M) 11’ 7” (3.5) | |

CLEANER AND CLOSER CUTTINGGet the cleanest and closest cut yet with the MowMax™ II PLUS true modular cutterbar. Faster knife tip speed, a slimmer cutterbar profile, and reshaped rock guards improve cut quality while providing a 30% lower cutting height. | |

TIME-SAVING INNOVATIONSThe standard QuickMax™ knife-change system and ShockPRO™ hubs are designed to save you hassle when you’re making hay. For additional peace of mind, the cutterbar is backed by a 36-month warranty. | |

PIVOT TO GREATER PRODUCTIVITYWhether you need a nimble mower to enter tight places or big capacity for wide-open spaces, four center-pivot models, with cut widths from 10- to 16-feet wide, are designed and built with pride in New Holland, Pennsylvania. | |

FROM WIDE SWATHS TO NARROW WINDROWSChoose the best conditioning system for your crops – rubber chevron rolls, steel chevron rolls, or high-contact chevron rolls.Choose between the chevron intermeshing rubber or steel rolls, or the LeaningEdge™ flail tine conditioning system to fit your needs. Enhanced swath control surfaces behind the conditioning system result in neater-looking swaths with improved dry down. |

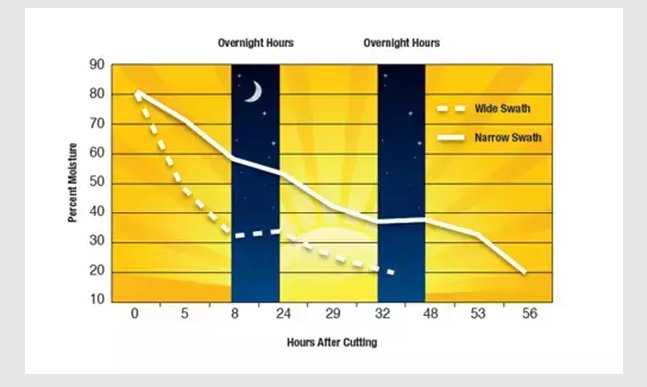

FROM WIDE SWATHS TO NARROW WINDROWSFast drying requires crop to be evenly distributed over a wide swath. To help, the Discbine® PLUS Series provides enhanced swath control surfaces behind the conditioning system. | |

THE ADVANTAGES OF SPREADING CROP WIDE AND THIN

| |

BETTER CONTROL MEANS BETTER WINDROWS

| |

WEDGES AND FINS

|

|

Type |

MowMax™ II PLUS true modular cutterbar |

|

Cutting width ft. in. (m) |

11’ 7” (3.5) |

|

Cutting height in. (mm) |

0.5 – 2.6 (12 – 65) |

|

Cutting height w/ opt. adjustable shoes in. (mm) |

0.5 – 5.6 (12 – 143) |

|

Number of discs / knives per disc |

7 / 2 |

|

Maximum disc speed @ 1,000 rpm PTO |

2250 |

|

Hydraulic tilt/cutting height control |

Standard |

|

Tilt angle degrees |

-2° to -10° |

|

Header flotation |

Vertical & lateral, adjustable springs |

|

ShockPRO™ disc drive protection system |

Standard |

|

3-year factory cutterbar warranty |

Standard |

|

Chevron intermeshing rubber rolls |

Optional |

|

Chevron intermeshing steel rolls |

Optional |

|

Length in. (mm) |

102 (2591) |

|

Diameter in. (mm) |

10.4 (264) |

|

Drive method |

Belt-driven, enclosed gearbox |

|

Speed rpm |

750 or 640 |

|

Conditioner roll tension adjustment |

Standard |

|

Conditioner gap adjustment |

Standard |

|

Compatibility |

Optional |

|

Number of tapered flail tines |

100 |

|

Length in. (mm) |

102 (2591) |

|

Diameter in. (mm) |

1400 |

|

Drive method |

Belt |

|

Speed rpm |

1042 or 752 with kit |

|

Conditioner gap adjustment |

Standard |

|

Swath width ft. (m) |

7 (2.1) |

|

Windrow width ft. (m) |

3 – 7 (.91 – 2.1) |

|

540 rpm, 6-spline 1-3/8” input speed |

— |

|

1,000 rpm, 21-spline 1-3/8” input speed |

Standard |

|

Slip and overrunning clutch protection |

Standard |

|

Drawbar swivel |

Standard |

|

Drawbar category |

ASAE Category II or III |

|

2-point semi-mount swivel |

Optional |

|

3-point hitch category |

ASAE Category II, III-N, or III |

|

Minimum PTO power hp |

85 |

|

Hydraulic requirement – rubber rolls |

1 double acting, 1 single acting |

|

Hydraulic requirement – steel rolls |

1 double acting, 1 single acting |

|

Hydraulic requirement – flails |

2 double acting |

|

Electrical |

7-pin connector for transport lights |

|

Transport width ft. in. (m) |

11’ 10” (3.6) |

|

Operating weight – rubber rolls lbs. (kg) |

5880 (2,667) |

|

Operating weight – steel rolls lbs. (kg) |

5980 (2,712) |

|

Operating weight – flails lbs. (kg) |

5760 (2,613) |