New Holland T9 with PLM Intelligence™ - T9.435 Wheeled

|

RATED HORSEPOWER @ RATED RPM PER SAE CV HP (KW) 370 (276) @ 2,000 RPM MAX. EPM HORSEPOWER @ 1900 RPM CV HP (KW) 425 (317) | |

|

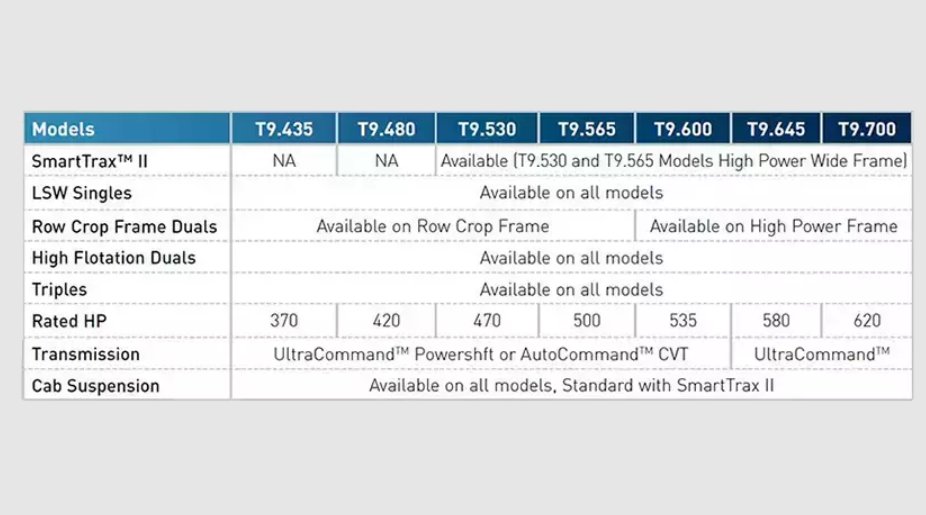

ULTIMATE POWER T9 models range from 425 to 682 max hp, with traditional Ultra Command™ full powershift transmission or the Auto Command™ CVT, in wheeled models or SmartTrax™ designs. | |

|

CAB ENHANCEMENTS Redesigned cab and controls, including the most functional and customizable armrest and display you’ll find, add new levels of comfort and convenience to your long and hectic days. | |

|

MAXIMUM VERSATILITY The IntelliView™ 12 display and Sidewinder™ Ultra armrest is second to none! We built your control package around the revolutionary idea that customer adjustments should come standard to increase your operator efficiency. | |

|

CONNECTED MACHINE Reduce downtime and keep operators in the field with added connectivity and support features. With remote viewing capabilities, you can access the in-cab IntelliView™ 12 display to help identify problems and gain deeper insight. |

THE TESTED AND RELIABLE POWER AND EFFICIENCY YOU’VE COME TO EXPECT FROM NEW HOLLANDYour T9 tractor is powered by an ECOBlue™ HI-eSCR (High Efficiency Selective Catalytic Reduction) Cursor engine developed by New Holland’s sister company FPT Industrial. These engines, which comply with the even-more-stringent Tier 4B emissions standards, offer you four key benefits: Performance: T9 engines offer more power, torque, torque back-up and engine power management while maintaining outstanding transient response. Efficient operation: Fluid consumption (diesel plus DEF) will be the same or better than Tier 4A T9 tractors. You also benefit from reduced life-long operating costs. Simplicity: The simpler engine solution ensures a higher power potential and the reduced cooling requirements mean more efficient operation. Consistency: There’s no change in vehicle operation compared to previous Tier 4A models. | |

INSIDE ECOBLUE™ HI-ESCRThis New Holland system delivers the highest NOx conversion efficiency in the industry. The patented SCR-only emission system is a true after-treatment system and works outside the engine. This allows the engines to produce class-leading power and reaps the benefits of better fuel efficiency compared to EGR/Diesel Particulate Filter (DPF)/SCR emissions system found in competitive models. This multi-patented system uses an Engine Control Unit, which not only manages the engine, but also the HI-eSCR after-treatment system by controlling the supply and dosing modules. Using a dedicated closed-loop system, it continuously monitors the NOx levels in the exhaust gases, ensuring that during every cycle the precise amount of DEF is injected to achieve NOx conversion of over 95%, all while guaranteeing low fluid consumption. | |

ECOBLUE™ HI-ESCR: YOUR POWER GUARANTEEECOBlue™ HI-eSCR technology has increased the power and already-exceptional productivity of your T9 tractor, independent of fuel quality, sulfur levels and without the need for costly diesel additives. That’s more power from less fuel with clean emissions. | |

| |

THE IMPORTANCE OF TRANSIENT RESPONSEAt New Holland, we’re passionate about transient response. It’s your productivity guarantee. Put simply, since your Cursor engine breathes only clean fresh air, it can react more quickly when placed under load—a lot more quickly in fact. So when you’re transporting heavy trailers or grain carts and you encounter a hill, you’ll be able to maintain constant forward speed with no slow down. Transient response. We’ve got it covered. | |

SAVE FUEL TO REDUCE YOUR CARBON FOOTPRINTEmissions released from burning diesel are a significant contributor to a farm’s overall carbon footprint. ECOBlue™ HI-eSCR technology for Tier 4B compliance reduces NOx emissions and maintains the T9 Series’ impressive fuel efficiency, bringing about a substantial cut in your farm’s carbon emissions. | |

| |

|

YOUR CHOICE OF COMPLETE CONTROL

| |

AUTO COMMAND™ CVT (T9.435 I T9.480 I T9.530 I T9.565 I T9.600)When you pair the extreme power of New Holland T9 Series 4WD tractors with the precise control of the Auto Command CVT, you make your workday more comfortable and productive in the most demanding conditions. It provides faster acceleration to road speed at 1,650 engine rpm, and gives you maximum speed control. Use three adjustable target speeds to match your every need. Simply set your target speed anywhere between 3.0 feet per minute right through 25 mph and regulate it to the nearest 0.01 mph. No steps. No range changes. Just seamless speed changes to match the jobs you do, from seeding to hauling and running grain carts. | |

SUPERIOR VERSATILITY AND EFFICIENCYThe Auto Command™ transmission allows for easier slow-speed operation, more precise speed control for high-value crops and added safety when backing up to hookup large implements. Using Auto Command saves you fatigue and fuel. You get automated efficiency without operator input, and can operate at peak power for any forward speed. | |

LIMITLESS CONTROL

| |

THE SIMPLICITY AND PEACE OF MIND OF ACTIVE STOPSTART

When you bring the tractor to a standstill, Auto Command™ prevents the tractor moving backwards or forwards, even with a heavy load. When you release the brake pedal, drive reengages and the transmission assures there is no risk of roll back on steep inclines. Imagine the efficiency you’ll gain when transporting or during frequent shuttling. That’s Active StopStart. | |

ULTRA COMMAND™ FULL POWERSHIFT TRANSMISSION

| |

Best-in-class power, torque, and overall fluid efficiencyThe T9.700 with Ultra Command™ powershift set new benchmarks in drawbar fuel efficiency, drawbar horsepower and maximum pull when tested by an outside independent testing organization. In fact, tests found the complete T9 Series tractor line features power, torque and overall fluid efficiency that lead this tractor class, which means better productivity and reduced operating costs for you. | |

SAVE TIME AND FUELThe latest Ultra Command™ improvements reduce the time it takes to shift and shuttle. You can shift from gear 1 to 16 in 20% less time and shift from forward to reverse 38% faster. The result: Ultra Command uses less fuel, decreases operating costs and reduces fatigue. | |

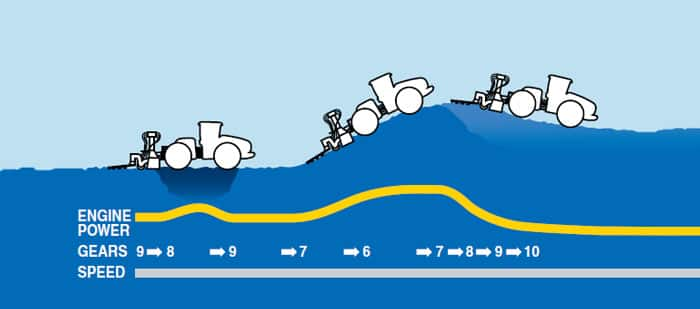

GSM. INTELLIGENT AUTOMATION

New Holland Ground Speed Management (GSM) is more than just an automated transmission shift system. Simple to set up and extremely efficient, GSM is a dependable way to reduce operator fatigue and fuel consumption to increase overall productivity. With CVT-like functionality, it uses a combination of data relating to engine load, forward speed and operator setting to manage both engine and transmission speeds to optimize performance and economy. | |

FIXED FORWARD SPEED? GSM TAKES CARE OF ITWhen load conditions change in the field, GSM automatically maintains a fixed forward speed. Just set your desired working speed and then select the GSM function. The automated system then matches engine and transmission speeds to maintain this fixed forward speed, to deliver the perfect balance between maintaining productivity without compromising economy. | |

FULL COMMAND IN TRANSPORT

During road transport, GSM automatically shifts the transmission according to load and throttle settings. With heavy loads, GSM downshifts to assist with engine braking on steep inclines. |

The ultimate in farming comfort

You’ll appreciate the all-new fit and finish and automotive quality of the T9 Series cab. The ergonomic, spacious and practical environment is a must for day-long productivity. New Holland offers you superior comfort and seating with two different cab options: The Deluxe Performance cab features a cloth seat with leather trim, a semi-active suspension and comfort-heating capabilities. For a premier seating experience consider the Luxury Performance cab. Enjoy semi-active suspension and heating capabilities in this seat too, but it’s also all-leather and is equipped with a ventilation system that cools and removes moisture to keep operators comfortable and productive when spending extended hours in the tractor. | |

All-day comfort

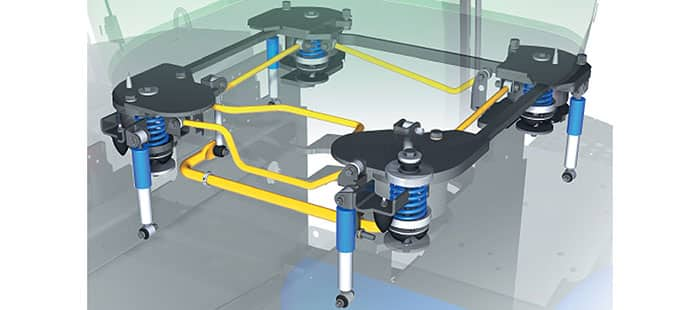

The exclusive four-point cab suspension masterfully controls front-to-back, side-to-side, and up-and-down motions to ensure that you are as comfortable after a long day’s work as you were before you started. | |

Settle in and enjoy the ride

The Comfort Ride™ cab suspension is revolutionary. All four corners of the cab are suspended on spring and damper units with a sophisticated anti-sway system to ensure you get a smooth and stable ride. The Comfort Ride suspension is offered on all models and is standard on SmartTrax™ II models. | |

Intuitive climate controls

The entire air-conditioning system has been redesigned with a powerful two-zone cooling system and precisely positioned vents to ensure whole body comfort. All controls have been ergonomically relocated to the SideWinder™ Ultra armrest, making on-the-go adjustments even easier. | |

Convenient and connected

We put more storage and cupholders in the newly redesigned cab than ever before to ensure maximum comfort. Technology has become part of our lives, too. You’ll always be connected with features like 26 total power charging outlets, 12V power ports, exterior camera inputs and a 120V power outlet to keep your devices fully powered. | |

High-quality audio

The integrated radio allows every operator to play their own MP3 music recording and receive crystal-clear radio signals. Get full access to weather radio channels, too. | |

Find the right position

The steering wheel now has separate tilt and telescopic adjustment as standard, which makes it even easier for you to select a comfortable working position—invaluable when spending long hours in the field or on the road. | |

LED power and performance

Lighting up the way for improved night-time productivity and total safety—it’s a key priority we achieve by bringing the latest automotive-sector innovations, like LED technology, into the farming world. For hardcore operators who work around the clock, you’re covered with our Performance Plus lighting package that provides 360-degree lighting system to turn darkness into light. As an added feature, all of our lighting packages can be configurable through the IntelliView™ 12 display to turn on or off certain light patterns. | |

SideWinder™ Ultra: the ultimate ergonomic farming experience.

T9 with PLM Intelligence™ tractors offer sophisticated features that are easy and intuitive to access. The SideWinder Ultra armrest hosts all key controls, including throttle, transmission and hydraulics. Everything you need to control is intuitively selected. More advanced features can be quickly accessed.

|

INTELLIGENT MONITORS FOR INTELLIGENT AGRICULTURE.

|

INFOVIEW™ DASH DISPLAY

|

FULLY CUSTOMIZABLE

|

PERFECT VIEW

|

A NEW LEVEL OF CONNECTIVITY AND PRODUCTIVITY.

|

CONNECTIVITY ACROSS YOUR OPERATION

|

GATEWAY TO PRODUCTIVITY

|

ADVANCED SUPPORT

|

UP TO 113 GALLONS PER MINUTE

|

SAVE TIME AND EFFORT WITH CUSTOM HEADLAND MANAGEMENT

|

UP TO EIGHT ELECTRONIC REMOTES

|

QUICK AND SIMPLE FLOW CONTROL SETTING

|

SMARTTRAX™ II: HIGH TRACTION, LOW COMPACTION

| |

HOW TO DECIDE ON THE BEST TRACKS OR TIRE OFFERING IN THE INDUSTRY

| |

HIGH FLOTATION OR ROW CROP DUALS, TRIPLES: LESS COMPACTION AND FUEL USAGE

| |

EXCLUSIVE SMARTTRAX™ DESIGN: PERFORMANCE ADVANTAGES THAT JUST KEEP ON PULLING.

| |

RUGGED DURABILITY, LESS MAINTENANCE, MORE UPTIME

• All bearings are sealed and lubricated for a lifetime with annual maintenance | |

LOW SIDE WALL TECHNOLOGY: SOLUTIONS FOR HIGH FLOTATION, HEAVY PULLING, AND ROADING APPLICATIONS ALL IN A SINGLE TIRE.

| |

THE DUAL AND TRIPLE THREAT: TIRE COMBINATIONS TO MEET YOUR ROW CROP OR HIGH-FLOTATION NEEDS.

| |

ROW CROP FRAME AND ROW CROP DUALS ARE PERFECTLY MATCHED FOR ROW-CROP APPLICATIONSSpring tillage, planting, post emergence side-dressing, grain carting, roading, and fall primary tillage—there is no application that the T9 with PLM Intelligence™ tractor can’t handle. | |

HIGH POWER WIDE FRAME AND HIGH FLOTATION DUALS PROVIDE THE POWER TO WHERE IT’S NEEDED

Heavy-pull applications call for the High Power Frame matched with high-flotation tires. Tire designs featuring improved traction capabilities are made for these kinds of applications. Grain cart applications with VF and IF dual tires (Row Crop Frame shown) allow for high-speed, low-pressure inflation, which lessens soil compaction while boosting fuel economy. Through less compaction, the T9 with PLM Intelligence™ tractor improves your harvest and yields the following year. | |

LSW SINGLES: LOW COMPACTION, NARROW-WIDTH ROADING

The next generation of tire solutions comes with Low Side Wall technology— powerful, rugged, balanced, and power hop resistance all wrapped up in a single tire solution. While increasing the rim diameter but not increasing the tire diameter, a lower side wall results in a tire with more stability for heavy pulling and roading applications and high ground area contact — yielding more productive results for your operation. |

UP TO 22,750-POUND HITCH LIFT CAPACITY

|

THE RIGHT BALANCE

|

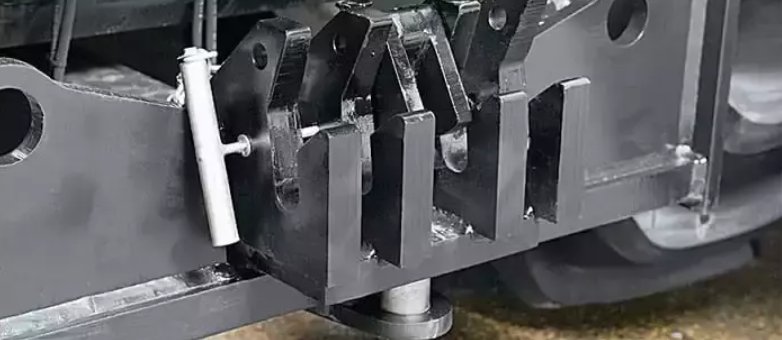

DRAWBAR OPTIONS TO SUIT YOUR NEEDS

|

T9 WITH PLM INTELLIGENCE™: BUILT SCRAPER READY

|

|

Engine* |

FPT Cursor 9 |

|

Rated horsepower @ rated RPM per SAE CV hp (kW) |

370 (276) @ 2,000 rpm |

|

Max. EPM horsepower @ 1900 rpm CV hp (kW) |

425 (317) |

|

PTO power @ rated 1811 engine rpm CV hp (kW) |

354 (264) |

|

Cylinders / Valves / Displacement cu. in. (L) |

6/24/531 (8.7) |

|

Engine aspiration |

Variable geometry turbo-charged, air-to-air after-cooled |

|

Torque rise % |

40 |

|

Factory-installed engine brake |

– |

|

Ultra Command™ powershift 16F/2R with 16 Hi (25 mph/40 kph) |

Standard |

|

Auto Command™ CVT (25 mph/40 kph) |

Optional |

|

Alternator/Battery/Electrical Cutoff Switch CCA |

12 V 200 amp/two 1,000 cranking amps/Yes |

|

Axle diameter: 5.0 in. (127 mm) planetary |

Standard |

|

Axle bar width: 120 in. (3048 mm) |

Standard |

|

Front/Rear auto differential lock |

Standard |

|

Main pump flow (Standard on full PowerShift)/ High flow option (Standard on CVT) gpm (LPM) |

40/55 (151/208) |

|

Optional MegaFlow™ II option pump flow Standard / High flow (Total flow available across all remotes) gpm (LPM) |

93/108 (351/408) |

|

Available flow at single remote valve gpm (LPM) |

35 (132) |

|

Drawbar lbs. (kg) |

Standard 6000 (2722), optional 11,000 (4990) |

|

Scraper drawbar lbs. (kg) |

- |

|

3-point hitch |

CAT IV-N (convertible to CAT III) |

|

Hitch lift capacity @ 24 in. lbs. (kg) |

20,000 (9072) |

|

Diesel capacity gal. (L) |

219 (829) |

|

Diesel Exhaust Fluid (DEF) capacity gal. (L) |

42 (159) |

|

Vertical tongue (maximum) |

11,000 (4990) |

|

Frame width |

36.5 (927) |

|

Wheelbase length in. (mm) |

148 (3759) |

|

Volume (size) / Glass 132 cu ft/88.1 sq. ft. |

Standard |

|

Wheel Models - Base Shipping Weight lbs. (kg) |

38,571 (17,496) |

|

Wheel Models - Max Gross Vehicle Weight lbs. (kg) |

49,500 (22,453) |

|

Track Models - Base and Max Gross Vehicle Weight lbs. (kg) |

– |

POWERED BY FPT INDUSTRIAL

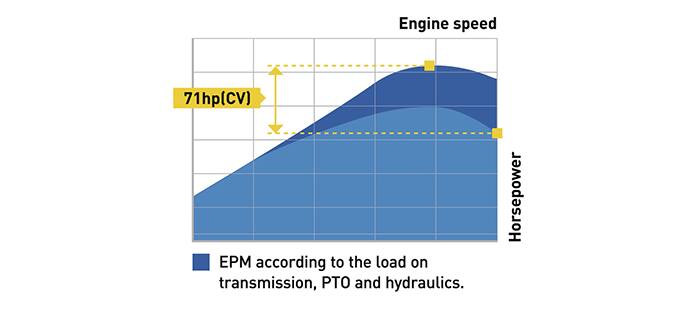

POWERED BY FPT INDUSTRIAL ENGINE POWER MANAGEMENT

ENGINE POWER MANAGEMENT DESIGNED FOR AGRICULTURE

DESIGNED FOR AGRICULTURE Select from two intuitive New Holland transmission choices – the traditional Ultra Command™ full powershift transmission or the Auto Command™ Continuously Variable Transmission (CVT) for ultimate precision and smooth control.

Select from two intuitive New Holland transmission choices – the traditional Ultra Command™ full powershift transmission or the Auto Command™ Continuously Variable Transmission (CVT) for ultimate precision and smooth control. The Auto Command™ responds to the amount of force you apply to the CommandGrip™ controller. Move the lever gently for gradual response, aggressively for quick response. Other controls are just as intuitive thanks to New Holland’s award-winning SideWinder™ II armrest with fully integrated IntelliView™ wide touchscreen display.

The Auto Command™ responds to the amount of force you apply to the CommandGrip™ controller. Move the lever gently for gradual response, aggressively for quick response. Other controls are just as intuitive thanks to New Holland’s award-winning SideWinder™ II armrest with fully integrated IntelliView™ wide touchscreen display.

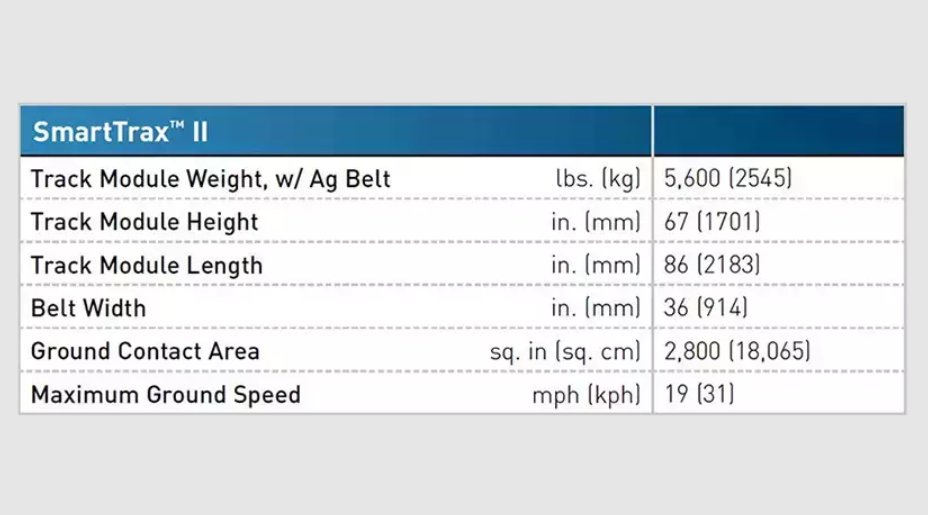

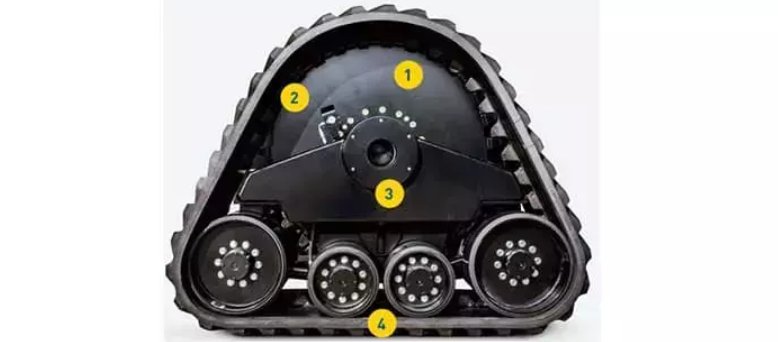

Put one of New Holland’s five T9 with PLM Intelligence™ SmartTrax tractors to work for you and you get the benefit of 2,800 square inches of ground contact per track module for a total footprint of 11,200 square inches. That maximizes traction, flotation and ride smoothness, while reducing ground pressure and compaction for minimal surface damage, and that improves soil fertility and water drainage, maximizing your yields.

Put one of New Holland’s five T9 with PLM Intelligence™ SmartTrax tractors to work for you and you get the benefit of 2,800 square inches of ground contact per track module for a total footprint of 11,200 square inches. That maximizes traction, flotation and ride smoothness, while reducing ground pressure and compaction for minimal surface damage, and that improves soil fertility and water drainage, maximizing your yields.

New Holland SmartTrax II gives your T9 Series tractor the lightest footprint and the heaviest pull, resulting in the ultimate-productivity tractor. SmartTrax II is a choice that best suits your terrain, your applications and your budget. And, only New Holland offers you two track lug options — the two-inch agricultural lug tread or the exclusive deep-traction lug tread with a 2.6-inch tread depth for added traction and pulling capability in very wet, loose, or soft soils.

New Holland SmartTrax II gives your T9 Series tractor the lightest footprint and the heaviest pull, resulting in the ultimate-productivity tractor. SmartTrax II is a choice that best suits your terrain, your applications and your budget. And, only New Holland offers you two track lug options — the two-inch agricultural lug tread or the exclusive deep-traction lug tread with a 2.6-inch tread depth for added traction and pulling capability in very wet, loose, or soft soils.