Vermeer 604 PRO G3 BALER

Built right. Right here.

Oncoming rain clouds can ruin a hay producer’s day. That’s why silage is quickly becoming a preferable option for producers everywhere who are tired of waiting on good weather and want high-quality forage for their cattle. According to Michigan State University Extension, silage harvested within five days of the optimal time has a feed quality advantage of $26.46 per ton over dry hay. For some producers, that’s reason enough to make the switch.

Of course, it takes a tough baler to handle the added tonnage of high-moisture hay.

The Vermeer Generation 3 604 Pro baler was specially designed and built from the ground up in Pella, Iowa, to handle the rigors of baling wet, heavy crops — combining strength and smart features while still giving you the versatility of having a baler that can bale dry hay.

Heavy-duty componentsThe G3 Pro baler is designed with a solid frame, heavy-duty components like large bearings, chains and rollers, and poly pickup bands to fit the needs of North American silage producers handling wet, heavy bales. |

Xtracut17 chopper systemXtracut17 chopper system cuts the crop for better bale density, fermentation, silage quality and digestibility. The pre-cut crop also provides a consistent material for additions to rations fed using a mixer wagon. |

Netwrap systemThe new netwrap system is designed for operator convenience with netwrap now in the back and the ability to adjust netwrap tension and monitor netwrap available on the roll. |

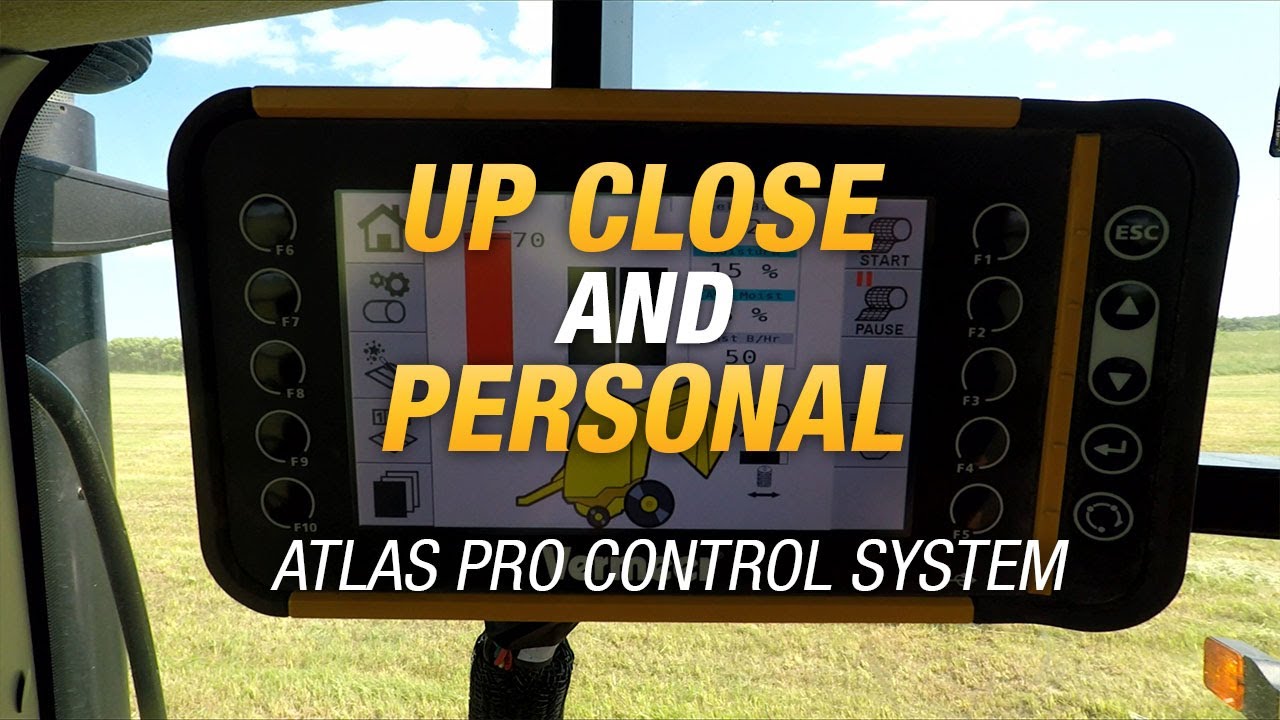

Atlas Pro control systemAtlas Pro™ control system is equipped with a 7-in (17.8-cm) color touchscreen display that gives operators advanced, real-time field statistics for up to 50 fields and allows you to view and adjust various baler settings including netwrap tension, bale density settings and monitor moisture levels all while in-cab. |