New Holland Tractors & Telehandlers

New Holland T7 Series - T7.230 SideWinder II

|

MAX. EPM HORSEPOWER - ISO TR14396- ECE R120 HP [CV] (KW) 225 (165) RATED ENGINE HORSEPOWER - ISO TR14396- ECE R120 HP [CV] (KW) 180 (132) | |

POWERFUL ADVANTAGES FOR ANY OPERATIONT7 models range from 150 to 300 engine horsepower, and all boast New Holland’s cutting-edge and award-winning ECOBlue™ Hi-eSCR 2 engine technology that optimizes torque, power and efficiency. | |

SUPERIOR COMFORT AND VISIBILITYBest-in-class lighting packages, upgraded seat options, Comfort Ride™ cab suspension and innovative easy-to-use controls improve operator comfort and productivity. | |

PRECISE CONTROL AND REDUCED OPERATING COSTSInnovative New Holland technology options such as IntelliSteer™ auto guidance, MyPLM™ Connect and IntelliCruise™ tractor/baler automation help maximize your profits. | |

EVEN MORE VERSATILITYThe T7 Series line-up provides a choice of engine power, hydraulic options and transmission choices for every application. |

THE POWER AND EFFICIENCY YOU’VE COME TO EXPECT FROM NEW HOLLANDT7 tractors boast New Holland's cutting-edge and award-winning ECOBlue™ HI-eSCR2 (High-Efficiency Selective Catalytic Reduction) engine technology, developed by New Holland’s sister company FPT Industrial. These engines comply with the even-more-stringent Stage V which exceeds Tier 4B emissions standards. These T7 engines continue to “breathe” better and maintain the performance advantages you’ve come to expect from the T7 Series line. | |

ECOBLUE™ HI-ESCR2 EXPLAINED

| |

CLEAN, HIGH-PERFORMANCE POWER

| |

EFFICIENT OPERATIONECOBlue™ HI-eSCR2 is an after-treatment system that does not interfere with or restrict the engine's performance, enabling it to maximize its efficiency and power. It does not require any exhaust gas to be recirculated through the engine and does not require regeneration of particulate filters. Total fluid consumption will be the same or better than equivalent Tier 4B machines, and this system allows New Holland to continue leading the industry with 750-hour service intervals. | |

PROVEN SIMPLICITY

| |

ENGINE SPEED MANAGEMENT

| |

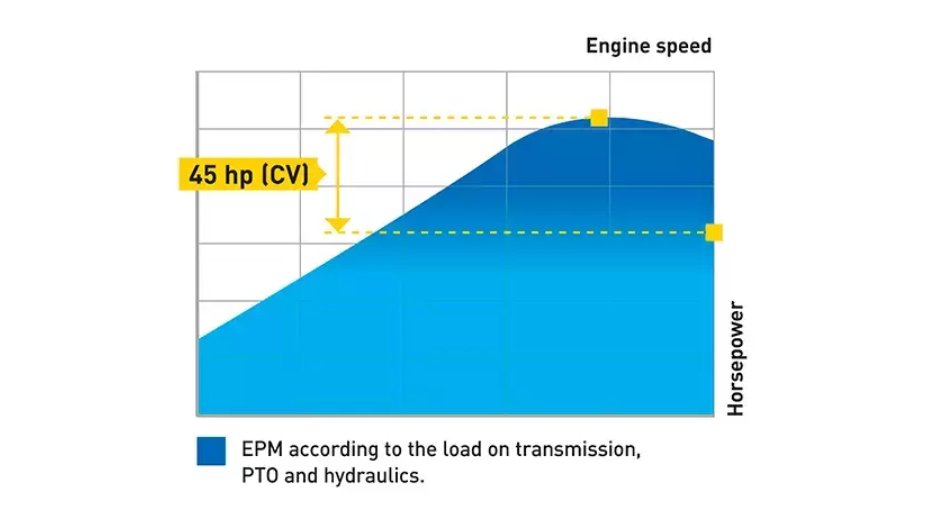

ENGINE POWER MANAGEMENT (EPM) WITH POWER BOOST

|

MEETING YOUR NEEDST7 Series tractors offer transmission choices for every application. Choose from the Auto Command™ (CVT), Power Command™ full powershift or the Range Command™ semi-powershift transmissions to make you work more efficiently. | |

AUTO COMMAND™ CVT

| |

MAKING THE MOST OF AVAILABLE TORQUENew Holland developed Auto Command™ transmissions to take advantage of the low running speed and high torque of New Holland engines. With the 31-mph Economy transmission, the engine runs at a fuel efficient 1550 rpm. | |

ACTIVE STOPSTARTA key safety feature of the Auto Command™ CVT transmission is Active StopStart. When the tractor comes to a standstill, the transmission prevents the tractor from moving backward or forward, even with a heavy load, so there’s no risk of roll back on steep inclines. For safe parking, you can easily engage an electronic brake using the shuttle lever. | |

BALANCING FUEL ECONOMY AND PRODUCTIVITYWhen working in Auto and Cruise modes, use the droop control button located to your right to reduce the engine speed needed to achieve maximum travel speed. The result: you reach 31 mph at much lower engine revolutions, saving you fuel. In PTO mode, you can regulate the acceptable reduction in PTO speed before forward speed is reduced. Perfect when operating in a field of uneven soil types with areas of compaction. | |

PUSH-BUTTON SIMPLICITY. YEARS OF PROVEN TECHNOLOGYThe Power Command™ transmission is a full-powershift that allows you to select the gear speed you want by simply pushing the upshift or downshift buttons. An optional shuttle-controlled electronic park brake enables you to use the shuttle lever to secure the tractor when neutral is selected. Only New Holland offers such a simple and secure transmission choice. | |

A SPEED FOR EVERY NEEDThe Auto Command™ transmission allows you to set a target speed between 0.01 mph right through to 31 mph. No steps. No range changes. Just seamless speeds to match your every need. | |

FULL POWERSHIFT FROM T7.190 TO T7.260Choose a standard 25-mph 18x6 or one of two optional, extra-high-ratio 19x6 transmissions—the Economy 19x6 that delivers 25 mph at a reduced engine speed or the Fast Mover transmission for 31-mph transport speed. | |

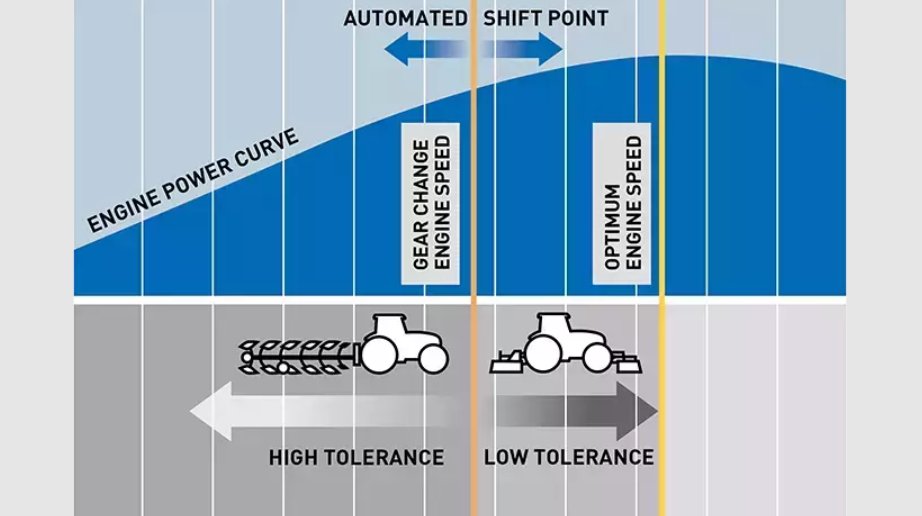

SMOOTHER SHIFTING IN FIELD AND TRANSPORTThe IntelliShift™ gear change management system delivers smooth gear changes all day long. It analyzes transmission load, speed and transmission oil temperature ensuring that your T7 Series tractor delivers a seamless powershift between each and every ratio. | |

EASY SHUTTLE

| |

WORK TOGETHER: AUTOMATION, COMFORT AND PRODUCTIVITY

|

THE PLACE TO GO FOR MORE SPACE AND BETTER VISIBILITYStep into a T7 Horizon™ cab, and you will find it has been designed to fit you perfectly. All-around visibility is as good as it gets, and the noise level is exceptionally low, at just 69 decibels. | |

THE ULTIMATE IN CONVENIENT CONTROLS

| |

COMMANDGRIP™ MULTIFUNCTION CONTROLLER

| |

INTELLIVIEW™ IV TOUCHSCREEN DISPLAY

| |

EYES IN THE BACK OF YOUR HEAD

| |

THE MOST COMFORTABLE SEATING PACKAGE

| |

A SMOOTH RIDEComfort Ride™ cab suspension provides the smoothest ride over bumpy ground. This simple mechanical system uses two isolation “donuts” at the front corners of the cab and a swaybar and two adjustable shock absorbers at the rear to isolate you from both up and down motions and side-to-side swaying. | |

DEPEND ON NEW HOLLAND FOR BRIGHT IDEAS

| |

CONTROL CENTER

|

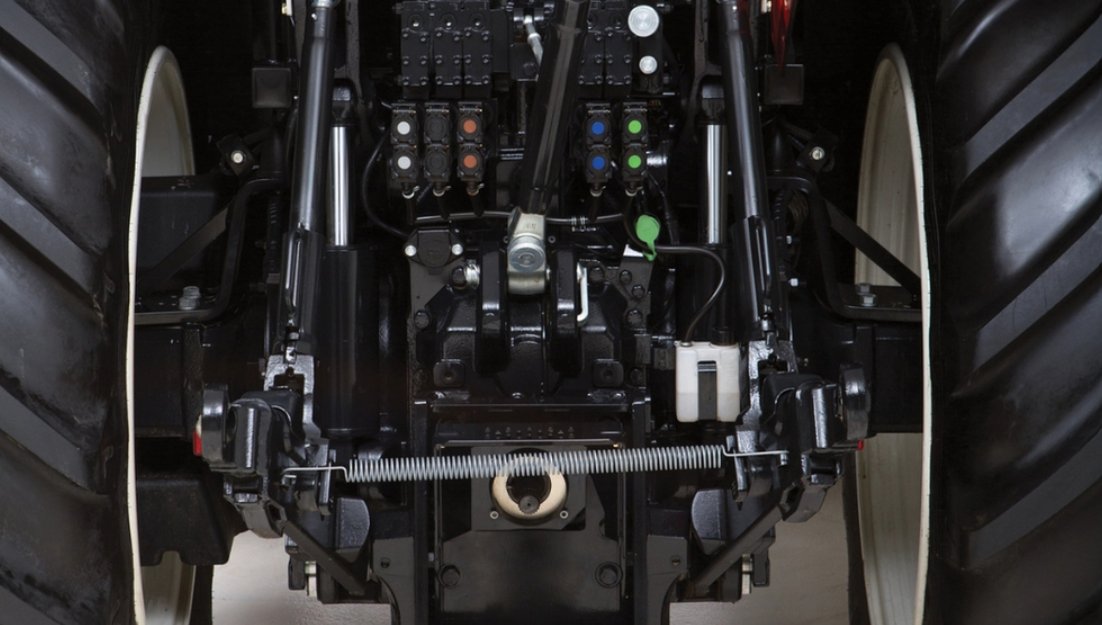

HYDRAULIC POWER TO MEET YOUR DEMANDSQuick response and ample oil flow are part of the design of the T7 Series hydraulic system. You have the capacity, control and flexibility to perform multiple hydraulic functions simultaneously—without sacrificing performance. |

CLOSED-CENTER LOAD-SENSING HYDRAULICSHydraulic efficiency makes an important contribution to the overall performance of the tractor. T7.190 to T7.210 models are fitted with a hydraulic pump that delivers 30 or 42 gallons per minute (gpm). 32- or 45-gpm pump is used on the T7.230 to T7.270. The new T7.290 and T7.315 models boosts a 44 hydraulic pump capacity. Get up to 58 gpm with MegaFlow™ for your most demanding hydraulic applications. T7 tractors equipped with the Auto Command™ CVT transmission benefit from a priority valve that guarantees optimum steering response in demanding hydraulic applications. For T7 models with the Range Command or Power Command™ transmission, a separate 17-gpm pump takes care of the steering. Full hydraulic power is always available at the remote valves and lift linkage, but only as much as is needed. The variable displacement pump only works on demand, which reduces fuel consumption. |

ELECTRONIC OR MECHANICAL - YOU DECIDE

|

ADJUST THE FLOW ON UP TO FIVE REMOTES

|

STRONG, EFFICIENT AND POWERFUL

|

POWER IMPLEMENTS ON FRONT OR BACK

|

AUTO PTO OPERATIONSelect Auto PTO and the PTO is automatically disengaged as the rear or front linkage is raised above a pre-set position. This protects the PTO shaft and tractor. The system re-engages the PTO as the linkage is lowered. |

|

New Holland Engine* |

Nef |

|

No. of cylinders / Aspiration / Valves / Emission level |

6/T/Stage V (exceeds Tier 4B) |

|

Selective Catalytic Reduction (SCR) system |

Standard |

|

Fuel system - high pressure common rail |

Standard |

|

Max. EPM horsepower - ISO TR14396- ECE R120 hp [CV] (kw) |

225 (165) |

|

Rated engine horsepower - ISO TR14396- ECE R120 hp [CV] (kw) |

180 (132) |

|

PTO horsepower hp (kw) |

150 (110) |

|

Rated engine speed (rpm) |

2200 |

|

Viscous coupled cooling fan |

Standard |

|

Reversible fan |

Optional |

|

Exhaust brake |

Optional |

|

Diesel tank capacity gal (liters) |

104 (395) |

|

DEF/AdBlue® tank capacity gal (liters) |

13 (48) |

|

Power Command™ full-powershift (40 kph) |

Optional |

|

Number of gears / with creeper (F x R) |

18 x 6 / 28 x 12 |

|

Min. speed / Min. speed with creeper mph (kph) |

1.2 / 0.2 (1.98 / 0.33) |

|

Power Command™ full powershift (40 kph ECO or 50 kph) |

Optional |

|

Number of gears / with creeper (F x R) |

19 x 6 / 29 x 12 |

|

Min. speed / Min. speed with creeper mph (kph) |

(1.2 / 0.2) 1.98 / 0.34 |

|

Auto Command™ continuously variable transmission (40 kph ECO) |

Standard |

|

Min. speed / Max. speed (mph) |

0.02 / 25 @ 1450 rpm |

|

Auto Command™ continuously variable transmission (50 kph ECO) |

Optional |

|

Min. speed / Max. speed (mph) |

0.02 / 31 @ 1550 rpm |

|

Closed Center Load Sensing (CCLS) |

Standard |

|

Main pump flow Standard / MegaFlow™ option*** gpm (Lpm) - (Range & Power Command) |

32 / 39.5 (120 / 150) |

|

Main pump flow Standard / MegaFlow™ option (Auto Command) |

39.5 / 45 (150 / 170) |

|

Electronic Draft Control (EDC) |

Standard |

|

Type |

Electro hydraulic |

|

Max. no. rear valves |

5 |

|

Joystick control |

Optional |

|

Max. no. mid mount valves |

3 |

|

Front Loader Ready |

Optional |

|

Rear Linkage |

Standard |

|

Front Linkage |

Optional |

|

Auto soft start |

Standard |

|

Engine speed at 540 / 1000 (rpm) |

1893 / 1950 |

|

Engine speed at 540E / 1000 (rpm) |

1569 / 1893 |

|

Engine speed at 1000 / 1000E (rpm) |

1912 / 1583 |

|

540 / 540E / 1000 / 1000E shiftable |

– |

|

Auto PTO management |

Standard |

|

Front PTO (1000 rpm) |

Optional |

|

Comfort Ride™ cab suspension |

Standard |

|

Headland Turn Sequence II System (HTS2) |

Standard |

|

IntelliView™ IV large screen 10.4” display |

Standard |

|

ISO 11783 connector |

Standard |

|

IntelliSteer™ auto guidance |

Optional |

|

4WD front axle |

Standard |

|

Suspended front axle |

Optional |

|

Supersteer™ front axle |

Optional |

|

Steering angle standard / Terraglide™ / SuperSteer™ axle (°) |

55 / 55 / 65 |

|

Bar rear axle |

Optional |

|

Standard front axle |

113.5 (2884) |

|

Suspended front axle |

113.5 (2884) |

|

SuperSteer™ front axle |

117.2 (2977) |

|

Minimum unballasted / shipping weight - Standard front axle lbs (kg) |

15,322 (6950) |

|

Minimum unballasted / shipping weight - Terraglide™ suspended front axle lbs (kg) |

16,094 (7300) |

|

Minimum unballasted / shipping weight - SuperSteer™ front axle lbs (kg) |

15,653 (7100) |

|

Max. permissible weight at 50 kph lbs (kg) |

28,660 (13000) |