New Inventory

Bourgault 8550

AIR CART LEGACY, PLUS, ADVANCED TECHNOLOGYThe 8000 Series Air Cart lineup offers a wide range of premium features in a tank configuration that continues Bourgault’s legacy as the air cart leader in the industry. Available in leading and trailing models, the 8000 Series is a winning solution for the progressive Producer who does not require the immense volumes of the 9000 I Series Air Carts. |

INDUSTRY-LEADING FLEXIBILITYUnbeatable Features in a Mid-Sized Series

|

- The X35 Apollo System Achieve unprecedented control of up to 6 products, as well as perform advanced seeding operations with the X35 Apollo System.

-

The ISO Apollo System Calibrate and perform basic rate control functions for up to 4 products with tractors equipped with universal terminals.

From the EZ™ Air Cart Hitch, to the rear-view camera and LED exterior tank lights, the 8000 Series allows you to work efficiently and safely.

- Safety catches on the tank lids prevent lid strikes if the Operator inadvertently opens the tank when pressurized.

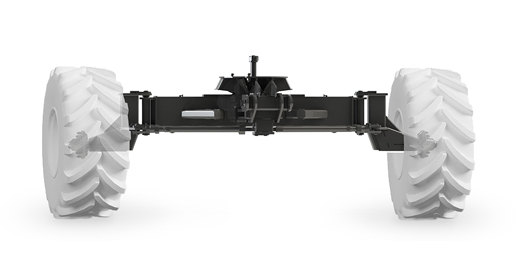

- Get "close enough" when pinning the air cart to the seeding implement with the EZ™ Air Cart Hitch.

- Increase rear visibility with the optional rear-view camera.

- Improve in-tank and exterior illumination with optional LED Lights.

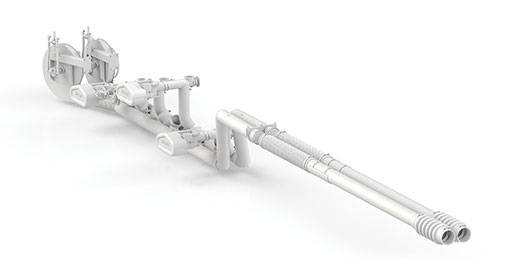

8000 Series Product Distribution System

The proven Bourgault Class A Metering System design has served Bourgault Customers since 1980. This tried-and-tested design is used yet today on the 8000 Series Air Carts.

The Class A Metering System consists of:

- the Straight-Through Primary Distribution System;

- Dual Auto Section Control™ (available on specific models);

- the PDM Pro™ Metering System;

- hydraulic calibration; and,

- fan options to match application requirements.

Whether you're using the Load/Unload Augers, the BagLift™ Product Transfer System, or the FillChute™; 8000 Series Air Carts have many options for easily and effectively transferring product.

- Load product quickly using the Load/Unload Auger;

- Lift bagged product effectively, and, at the same time, save your back from strain with the BagLift™ Product Transfer System;

- The FillChute™ is an option for units equipped with the Saddle Tank™.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Cart Volumes The ratios between the various compartments of each model have been calculated to deliver maximum product flexibility and increased convenience resulting in less stops in the field. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

* 9650 & L9650 available with optional 3 meter tire spacing with high capacity single tires; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

AIR CART FAN REQUIREMENTS Hydraulic Requirements & Recommendations

Minimum Fan Speed Requirements Each air cart is equipped with a Minimum Fan Speed Chart Manual to identify the best starting point for specific products. |