New Inventory

New Holland Discbine® 313/316 Center-Pivot Disc Mower-Conditioners

FAST, SMOOTH CUTTINGYou can rely on genuine Discbine® disc mower-conditioners for smooth, trouble-free mowing, even in tough conditions. | |

THE SHOCKPRO™ HUB ADVANTAGEShockPRO™ disc hubs protect the cutterbar by absorbing harmful impacts and can be changed quickly so you’re back making hay quickly. | |

MOWMAX™ II DISC CUTTERBAR 3-YEAR FACTORY WARRANTYThe reliability of the MowMax™ II true modular disc cutterbar is backed by three full years of complete warranty coverage. It includes one full year of base factory warranty, plus two additional years of disc cutter bar coverage. It’s peace of mind direct from the New Holland factory, so cut close with confidence. | |

WIDEDRY™ CONDITIONINGNew Holland’s WideDry™ conditioning systems produce a thinner crop mat for smoother crop flow, more uniform conditioning and faster drydown. | |

CLOSER CUTTING. FASTER DRYDOWN. INCREASED DURABILITYCenter-pivot Discbines are redefining the disc mower-conditioner industry by taking mowing performance to new levels. The 13-foot Discbine 313 and 16-foot, three-inch Discbine 316 are designed with increased durability and features that lead to cleaner cutting, more efficient crop flow, and smoother, more effective conditioning.

| |

MOWMAX™ II DISC CUTTERBARThis is a cutterbar designed for the higher demands of large harvesting operations. It incorporates the large discs and heavy-duty components also found on Durabine™ disc heads for New Holland Speedrower® self-propelled windrowers. The Discbine 313 and 316 make quick work of cutting hay and preparing your crop for baling or chopping, whether you’re mowing alfalfa, clover, orchard grass, timothy, bermuda grass, bahia, grass, fescue, cereal rye, forage wheat or oats. | |

PEACE OF MIND DIRECT FROM THE FACTORYWhen you buy any new Discbine® hay mower equipped with a MowMax™ or MowMax™ II disc cutterbar, you’re covered with one full year of base factory warranty, plus two additional years of disc cutterbar coverage. Cut confidently. Cut with New Holland. | |

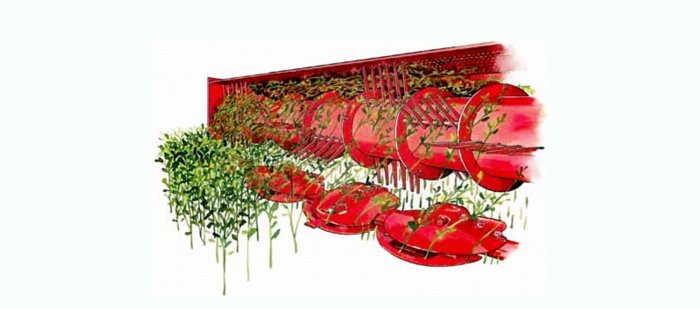

FAST DRYDOWNYou’ll produce nutritious, high-value feed with your choice of three WideDry conditioning systems. Choose the gentle conditioning of rubber chevron-intermeshing rolls that save delicate leaves, steel chevron rolls for winter forage or long-stem and cane grasses, or LeaningEdge™ flail tines for fast drying of grass hay. | |

SIMPLIFIED DRIVELINESThe new MowMax II cutterbar’s smart design allows driving the cutterbar from only one end, which simplifies maintenance and leaves the top of the header uncluttered. All u-joints are easily accessible for servicing, and the lube interval has been extended to 50 hours so you spend less time on maintenance.

| |

SWIVEL HITCH OPTIONSChoose either the drawbar swivel hitch or two-point swivel hitch and get maximum turning performance with zero driveline wrap-up. PTO power is transferred from the front swivel gearbox to a second swivel gearbox at the rear of the tongue that maintains perfect alignment of the output driveshaft to the cutterbar- and conditioner-drive gearbox on the left side of the unit. | |

SIMPLE MAINTENANCE. EASIER ACCESSNew Holland has made access to the discs and drive components easier than ever. Poly bifold upper shields are light, foldable and easy to lift, and they’re more impact-resistant to dents from foreign objects. The driven-end access steel door is double layered to resist denting in that area too. Material overlap keeps curtains in place without the need for clips or magnets. |

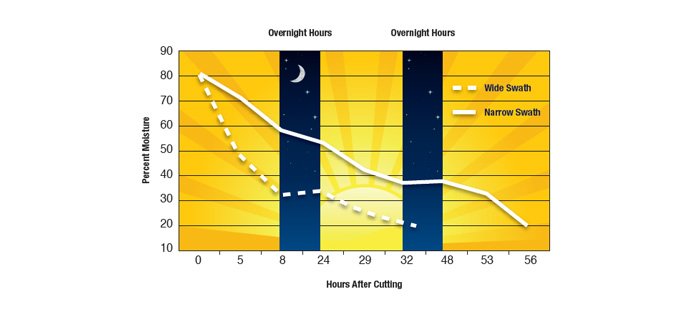

WIDE SWATHS. FAST, EVEN DRYINGNew Holland’s WideDry™ conditioning systems are over 22% wider than the conditioning systems on previous Discbine models. This results in a thinner crop mat that feeds smoothly through the conditioning system. Uniform conditioning aids in faster drying in the field. Crop transitions more smoothly from the cutterbar to the conditioning system, reducing crop feeding issues, particularly in thick grasses, cane, and other high-volume crops. | |

THE ADVANTAGES OF SPREADING WIDE AND THINThe Discbine 313 and 316 disc mowers allow you to lay down a wide swath for more sun exposure and better natural drying. Wedges are mounted on the rear swath board to help spread the crop mat. Customize your windrow and swath formation using the longer, adjustable windrow shields and a swath gate that features rubber flashing for improved crop flow and a new spring-assist adjustment lever for easy changes. University tests confirm that the more leaves are exposed to the sun, the faster crops dry and the more feed value is retained. Quick drying reduces sun bleaching and gives you an advantage when you need to beat the weather and bale or chop before the rain.

| |

YOUR CHOICE OF CONDITIONINGChoose from chevron-patterned intermeshing rubber or steel rolls, or LeaningEdge™ flails to suit your conditioning needs.

| |

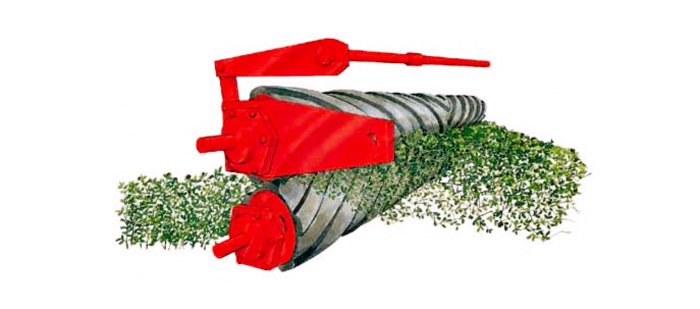

CHEVRON INTERMESHING RUBBER ROLLSGentle chevron rubber intermeshing rolls provide full-stem crimping and cracking with a scrubbing action while handling the leaves of high-value feeds delicately, making it the ultimate solution for alfalfa and clover. This is possible because of the large 10.4-inch roll diameter, the rubber compound, the intermeshing fit and profile of the lugs. These features work together to grip the crop and generate an even flow of crop through the rolls to provide an even spread into fast drying swaths or windrows.

| |

CHEVRON INTERMESHING STEEL ROLLSDurable chevron steel intermeshing rolls are designed for use with all crops, but show a real advantage in cane-type crops, grain forage crops and extra-tall grass crops. The chevron pattern of the steel lugs provides aggressive full-stem crimping, smooth crop flow, and even distribution into fast drying swaths or windrows. Rugged all-steel roll construction resists wear better than rubber, providing a long life even in highly abrasive conditions.

| |

TORSION-BAR ROLL PRESSUREYear after year, New Holland’s torsion-bar roll-pressure system is proven to be the most effective design for delivering consistent, thorough conditioning. The no-tools-required hand crank makes it easy to tailor roll pressure to the crop without crawling under the machine with wrenches. The unique, over-center linkage momentarily relieves roll pressure, allowing crop slugs or foreign objects to pass without plugging for non-stop mowing.

| |

CONDITIONING ROLL SPEED ADJUSTMENTSRoll conditioning systems generate air movement that can blow lighter crop away from the cutterbar and adversely affect cutting quality. To help prevent this, you can slow roll speed from 750 rpm to 640 rpm by switching the sheaves on the roll drive. The decreased roll speed minimizes air bursts while maintaining cutterbar speed to provide excellent cut quality in light crop conditions.

| |

LEANINGEDGE™ FLAILSFor fast drying of grass hay, choose New Holland LeaningEdge flail conditioning. The 20-degree tangent of LeaningEdge flails creates more outward pressure, pushing crop against the adjustable conditioning hood for more thorough conditioning. The semi-swinging design ensures crop is released at the ideal moment to form uniform, fast-drying swaths or windrows. For lighter conditioning of delicate crops, raise the hood away from the flails. Or, for maximum conditioning, lower the hood to increase the crop friction. An optional textured hood liner offers even more aggressive conditioning of difficult crops. For more delicate handling of legumes and delicate grasses, an optional slow-speed kit is also available for the LeaningEdge flail conditioning system.

|

CHANGE KNIVES MORE QUICKLYThe QuickMax knife change system is available for all MowMax™ II disc cutterbars as a factory option or you can upgrade your current machine by contacting your authorized New Holland dealer. | |

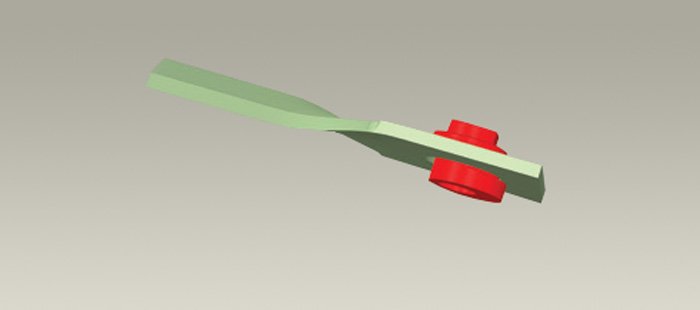

SAVES PRECIOUS TIMETime is precious when you’re making hay, and the new QuickMax system allows you to quickly change damaged knives or flip an entire set so you’re back clean-cutting quickly. Because the QuickMax system allows you to change knives with discs at a 45-degree angle to the cutter bar, you can change blades in just one-half rotation of the cutterbar, saving you time compared to changing traditional bolted knives. Patented New Holland knife-lock technology assures knife retention in the most difficult conditions. Best of all, the system does not require the use of special blades. It works with any approved New Holland knives for your machine. | |

HOW IT WORKSPatented eccentric knife nut design- A notch on the back of each blade attachment nut ensures best-in-class knife retention.

| |

Unique Blade-change toolThe tool pries the spring plate down to release the knife from the patented knife nut, quickly releasing each blade. Check for wear of the knife nut with the integrated gauge on the tool. Flip the existing blade or swap it out for new then stow the special tool on board your Discbine™ 313 and 316 models for quick in-field blade changes.

| |

Unique rock guardsEvery new MowMax™ II cutterbar features specialized rock guards to accommodate the QuickMax tool. The specialized design allows you to change knives by rotating the disc just 180 degrees one time instead of the four individual disc rotations required on competitive models.

|

|

Discbine® 313 (flail) | |

| Number of discs | 8 | |

| Cutting Width | 13 ft., 0 in. | |

| Conditioning system | Flails | |

| Tongue Design | Center Pivot |

|

Discbine® 313 (roll) | |

| Number of discs | 8 | |

| Cutting Width | 13 ft., 0 in. | |

| Conditioning system | Chevron intermeshing molded rubber rolls, chevron intermeshing steel rolls | |

| Tongue Design | Center Pivot |

|

Discbine® 316 (roll) | |

| Number of discs | 10 | |

| Cutting Width | 16 ft., 3 in. | |

| Conditioning system | Chevron intermeshing molded rubber rolls, chevron intermeshing steel rolls | |

| Tongue Design | Center Pivot |

| Name | Link |

| Discbine® 313/316 Center-Pivot Disc Mower-Conditioners - Brochure | Download |