New Holland Haytools & Spreaders

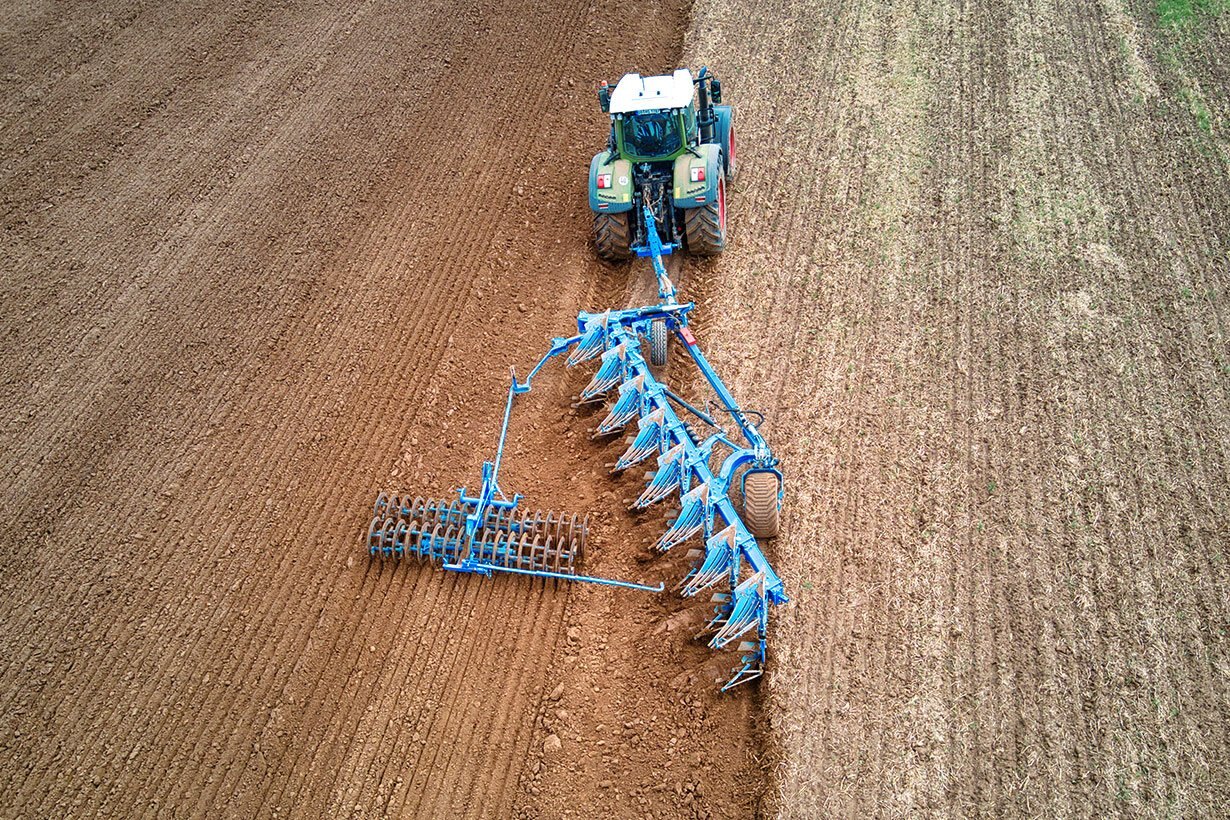

Lemken Diamant 16

|

The semi-mounted plough for the highest requirementsDiamant 16 is built for performance and equipped with all our technologies to help you achieve a high level of productivity. On the road or in the field, you will appreciate the comfort! |

For more clearance

|

More grip, better traction

|

OptiLine: Pull smart, save fuel |

Onland or in the furrow? OF can do both!

|

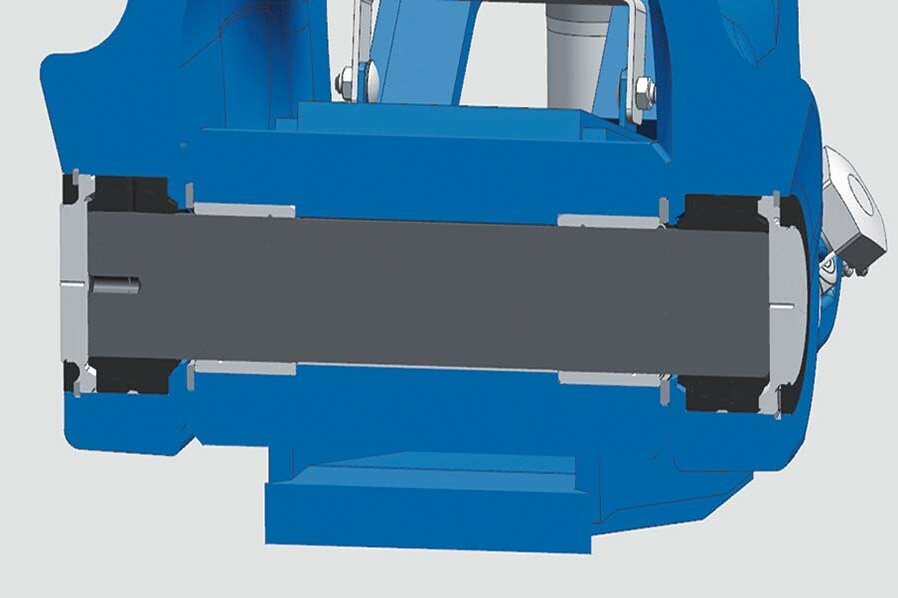

Horizontal draw point adjustment

|

Superior safety & reliability

|

Quality & safety on the road

|

Comfortable working depth adjustment

|

|

| Diamant 16 5 L 100 | Diamant 16 5+1 L 100 | Diamant 16 6 L 100 | Diamant 16 6+1 L 100 | Diamant 16 7 L 100 | Diamant 16 7+1 L 100 | Diamant 16 8 L 100 | Diamant 16 8+1 L 100 | Diamant 16 5 L 120 | Diamant 16 5+1 L 120 | Diamant 16 6 L 120 | Diamant 16 6+1 L 120 | Diamant 16 7 L 120 | Diamant 16 7+1 L 120 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power requirements (hp) minimum of | 150 | 150 | 150 | 150 | 150 | 150 | 180 | 180 | 150 | 150 | 150 | 150 | 150 | 180 |

| Power requirements (kW) minimum of | 110 | 110 | 110 | 110 | 110 | 110 | 132 | 132 | 110 | 110 | 110 | 110 | 110 | 132 |

| Weight (kg) | 2 584 | 2 834 | 2 830 | 2 830 | 3 076 | 3 326 | 3 322 | 3 572 | 2 634 | 2 896 | 2 892 | 3 154 | 3 150 | 3 412 |

| Article number | 80 4001L | 80 4002L | 80 4001L | 80 4003L | 80 4005L | 80 4006L | 80 4007L | 80 4008L | 80 4009L | 80 4010L | 80 4011L | 80 4012L | 80 4013L | 80 4014L |

| Working width per furrow (cm) | 33, 38, 44, 50 | 33, 38, 44, 50 | 33, 38, 44, 50 | 33, 38, 44, 50 | 33, 38, 44, 50 | 33, 38, 44, 50 | 33, 38, 44, 50 | 33, 38, 44, 50 | 40, 45, 53, 60 | 40, 45, 53, 60 | 40, 45, 53, 60 | 40, 45, 53, 60 | 40, 45, 53, 60 | 40, 45, 53, 60 |

| Number of furrows | 5 | 5+1 | 6 | 6+1 | 7 | 7+1 | 8 | 8+1 | 5 | 5+1 | 6 | 6+1 | 7 | 7+1 |

| Body spacing (cm) | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 120 | 120 | 120 | 120 | 120 | 120 |

|

| Name | Link |

| Brochure | Download |